Hydratech FMS division provides specialist engineering and maintenance services to customers installing, commissioning, operating or optimising large cooling and heating systems.

More about Hydratech ServicesWorking with industry leaders

A key objective since Hydratech's formation in 1998, has been the establishment of technical partnerships with those responsible for industrial and commercial heating system design, installation, and operation - to improve efficiency, save energy and avoid costly downtime.

Hydratech's engineers, chemists and analysts work with high-profile clients across many business and industry sectors, to implement a fully integrated approach to hydronic fluid selection and management - which in turn, maximises the potential for optimised performance, reduced operational costs and significant return on investment gains.

Hydratech's holistic approach to industrial and commercial heating system optimisation encompasses:

Fluid Selection

Heat transfer fluid (glycol, antifreeze, brine etc) characteristics have a direct and long-lasting impact on commercial and domestic heating system performance, production output, energy consumption and operational lifespan. Fluid thermodynamics, toxicity, corrosion chemistry and aerobic bacteria, are all key considerations when selecting an appropriate formulation, mixing ratio and compatible inhibitor package.

For nearly 25 years, Hydratech have been assisting the industrial and commercial heating industry with fluid selection - utilising over 100 years combined experience. Whether your priority is cost, thermal efficiency, environmental impact, toxicity, corrosion resistance or a combination of all these, Hydratech has a fluid to suit. Contact our fluid experts here.

Fluid Monitoring

Based on many years of experience, it is not uncommon for the maintenance of heating systems (industrial and domestic) to be overlooked. Under such circumstances various issues can develop, including advanced corrosion, biological fouling and sediment formation. All of which will have a direct and negative impact on heat transfer efficiency, pumping performance and energy consumption.

Hydratech’s in-house laboratory carries out analytical fluid testing of heating system fluids, primarily microbiological and chemistry testing - to identify water contaminates, bacterial presence, water treatment levels or the make-up of elements. More on fluid monitoring here.

Fluid Management

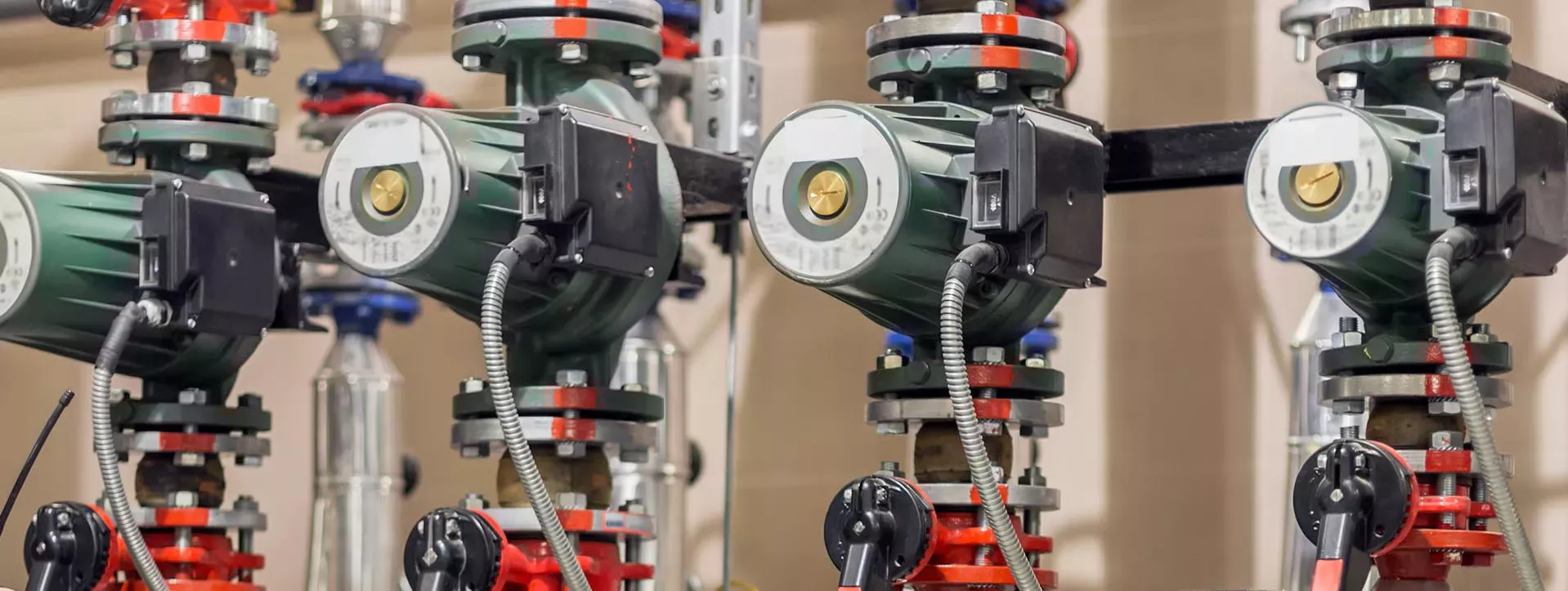

Correct maintenance of hydronic systems is essential if heating system efficiency is to be optimised and operating costs are minimised. Hydratech Fluid Management Services (FMS) provide specialist engineering and maintenance services to customers installing, commissioning, operating, or optimising large hydronic systems.

By combining expertise in water-treatment chemistry, fluid-thermodynamics and mechanical engineering, Hydratech FMS division provide a comprehensive range of services to maximise heating system efficiency, minimise downtime and reduce risk. More on Hydratech Services here.